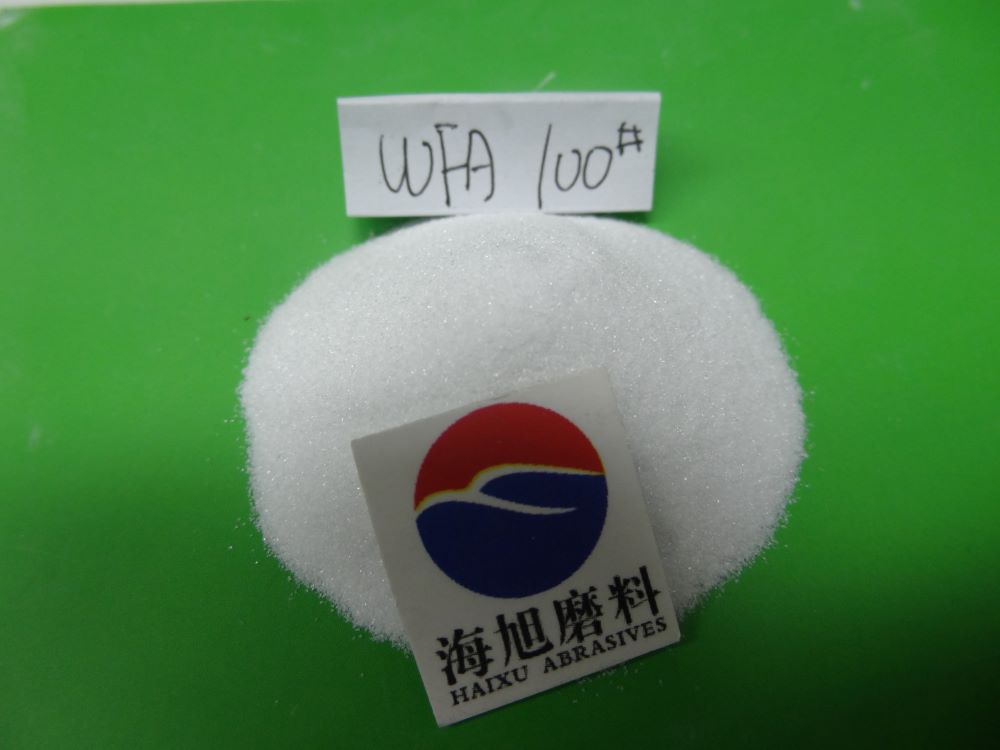

white fused alumina F100 F220 for tumbler polishing machine

white fused alumina F100 F220 for tumbler polishing machine was made from the high quality alumina by melting above 2000 in the electric arc furnace and cooling. It is white with the main crystal phase α-Al2O3.The white alumina produced in titling electric arc furnace has the advantage of high bulk density and low porosity and the volume stability and thermal shock resistance can be improved.

PHYSICAL PROPERTIES

| Specific Weight | 3.96 g/ cm3 |

| Mohs Hardness | 9.0 |

| Crystal form | α-Al2O3 |

| Melting Point | 2250℃ |

TYPICAL CHEMICAL ANALISIS [%]

| Al2O3 | Fe2O3 | FeO | MgO | CaO | TiO2 | Na2O | K2O | LOI |

| 99.5 | 0.04 | / | 0.01 | 0.01 | / | 0.25 | 0.01 | < 0.09 |

Why Choose Our White Fused Alumina for Your Polishing Tumbler?

-

Exceptional Hardness & Sharpness: With a Mohs hardness of 9.0, our WFA grains are among the hardest synthetic abrasives available. This ensures aggressive and efficient cutting action in the initial stages (ideal for F100) and a refined finish in the secondary stages (perfect for F220), significantly reducing cycle times.

-

High Purity & Chemical Stability: Manufactured from high-grade alumina, our white fused alumina is free from iron sulfide and other contaminants. This purity makes it non-reactive, preventing rust stains or chemical etching on workpiece surfaces. It is the optimal choice for finishing stainless steel, titanium, aluminum, brass, and other sensitive metals without risk of contamination.

-

Friability & Self-Sharpening: These grains possess controlled friability, meaning they fracture under pressure to reveal fresh, sharp cutting edges throughout their service life. This self-sharpening property ensures a consistent cut rate and finish quality from the beginning to the end of the media’s lifespan, unlike pre-formed media that wears down and becomes blunt.

-

Precise Mesh Sizing: Our F100 (medium grit) and F220 (fine grit) are carefully graded to provide uniform particle size distribution. This consistency prevents lodging in complex part geometries, ensures even flow within the tumbler, and guarantees repeatable, predictable results batch after batch.

-

Cost-Effective Performance: Due to its extreme durability and long life, White Fused Alumina media offers a lower cost-per-cycle compared to many conventional options. It complements other media types (like ceramic pre-forms or plastic pellets) perfectly and can be used in both wet and dry tumbling processes.

Mainly Applications of white fused alumina F100 F220:

-Bonded Abrasives and Coated abrasives

-Creating a matt finish on glass

-Wet and dry blast media,grinding and polishing etc

-Floor/Wall laminates,Wear-resistant

-Thermal spraying/plasma spraying,Processing very hard component

-Catalyst Carrier

-Ceramic and Tiles,Ceramic filter plate,ceramic membrane etc

-Grinding wheels,Cup wheels,Whetstone,polishing pads etc

-Blast-cleaning,surface finishing,Deburring,Roughening metallic surfaces