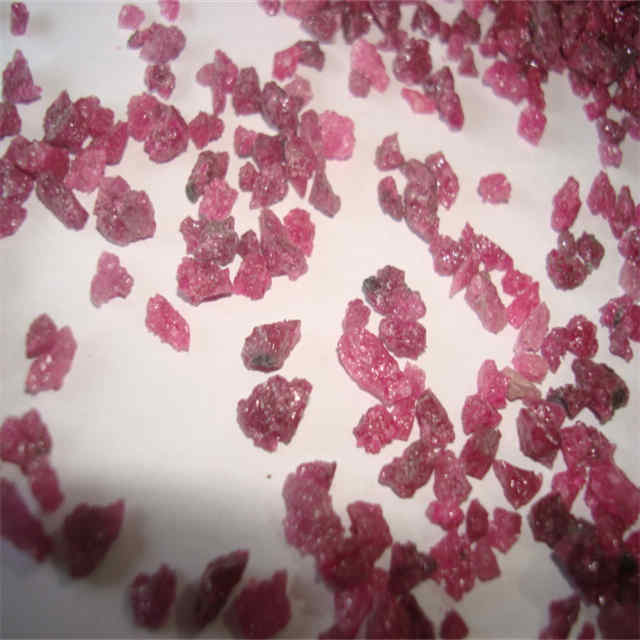

Pink fused alumina A98

Pink Fused alumina is bayer alumina,which is electrically fused in high temperature,being added with the right quantity of oxidized chromium. lt is pink.lts hardness is close to,but toughness higher than that or WA.The abrasive tools made of it feature excellent durability and high processing cleanness,which are suitable for the precision grinding of the measuring tools,lathe main shafts, instruments and apparatus parts,threading workpieces and samplers,etc.

PHYSICAL PROPERTIES

| Basic minerals | α-Al2O3 |

| Crystal size μm | 600-2000 |

| True density g/cm3 | ≥3.90 |

| Bulk density g/ cm3 | 1.40-1.91 |

TYPICAL CHEMICAL ANALISIS [%]

| Low chromium | Medium chromium | High chromium | ||||||

| Al2O3

(%) |

Cr2O3

(%) |

Na2O

(%) |

Al2O3

(%) |

Cr2O3

(%) |

Na2O

(%) |

Al2O3

(%) |

Cr2O3

(%) |

Na2O

(%) |

| ≥98.50 | 0.20-0.45 | ≤0.50 | ≥98.20 | 0.45-1.00 | ≤0.55 | ≥97.40 | 1.00-2.00 | ≤0.55 |

1.Used for refractory,casting,foundry and Painting etc

Sizes:0-1mm 1-3mm 3-5mm 5-8mm

2.Used for abrasives,blasting,grinding,ceramic,rust removal,surface treatment, floor coating,abrasion resistant layer etc

TPARTICLE SIZE DISTRIBUTION

| F8 | +4000um | 0 | +2800um | ≤20% | +2360um | ≥45% | +2360+2000um | ≥70% | -1700um | ≤3% |

| F10 | +3350um | 0 | +2360um | ≤20% | +2000um | ≥45% | +2000+1700um | ≥70% | -1400um | ≤3% |

| F12 | +2800um | 0 | +2000um | ≤20% | +1700um | ≥45% | +1700+1400um | ≥70% | -1180um | ≤3% |

| F14 | +2360um | 0 | +1700um | ≤20% | +1400um | ≥45% | +1400+1180um | ≥70% | -1000um | ≤3% |

| F16 | +2000um | 0 | +1400um | ≤20% | +1180um | ≥45% | +1180+1000um | ≥70% | -850um | ≤3% |

| F20 | +1700um | 0 | +1180um | ≤20% | +1000um | ≥45% | +1000+850um | ≥70% | -710um | ≤3% |

| F22 | +1400um | 0 | +1000um | ≤20% | +850um | ≥45% | +850+710um | ≥70% | -600um | ≤3% |

| F24 | +1180um | 0 | +850um | ≤25% | +710um | ≥45% | +710+600um | ≥65% | -500um | ≤3% |

| F30 | +1000um | 0 | +710um | ≤25% | +600um | ≥45% | +600+500um | ≥65% | -425um | ≤3% |

| F36 | +850um | 0 | +600um | ≤25% | +500um | ≥45% | +500+425um | ≥65% | -355um | ≤3% |

| F46 | +600um | 0 | +425um | ≤30% | +355um | ≥40% | 355+300um | ≥65% | -250um | ≤3% |

| F54 | +500um | 0 | +355um | ≤30% | +300um | ≥40% | +300+250um | ≥65% | -212um | ≤3% |

| F60 | +425um | 0 | +300um | ≤30% | +250um | ≥40% | 250+212um | ≥65% | -180um | ≤3% |

| F70 | +355um | 0 | +250um | ≤25% | +212um | ≥40% | +212+180um | ≥65% | -150um | ≤3% |

| F80 | +300um | 0 | +212um | ≤25% | +180um | ≥40% | +180+150um | ≥65% | -125um | ≤3% |

| F90 | +250um | 0 | +180um | ≤20% | +150um | ≥40% | +150+125um | ≥65% | -106um | ≤3% |

| F100 | +212um | 0 | +150um | ≤20% | +125um | ≥40% | +125+106um | ≥65% | -75um | ≤3% |

| F120 | +180um | 0 | +125um | ≤20% | ≥40% | ≥40% | +106+90um | ≥65% | -63um | ≤3% |

| F150 | +150um | 0 | +106um | ≤15% | +75um | ≥40% | +75+63um | ≥65% | -45um | ≤3% |

| F180 | +125um | 0 | +90um | ≤15% | +75um | * | +75+63um | ≥40% | -53um | * |

| F220 | +106um | 0 | +75um | ≤15% | +63um | * | +63+53um | ≥40% | -45um | * |

Mainly Applications

-Various grinding wheels,vitrified griding wheels and coated abrasives

-Dry&wet blast abrasive

-Fine blasting

-Refractories and Furnace Linings

-Glass & Ceramics:Decorative marking&Frosting & line marking

-Metals:Removal of hard deposits/investment/paint/scale/rust/solder/weld/flex/

-Castings and Forgings

-Lapping and Polishing/Lapidary/Optical

-Nuclear and Power Generation

-Oil and Gas Industries

-Plastics & Composites: Preparation for paint or metal sprayings