Description of White Fused Alumina

White Aluminium (also known as white aluminium oxide or White Corundum) is made of industrial alumina powder as the main raw material, which is smelted in an electric arc furnace at a high temperature of more than 2000 degrees and then cooled. It is a high-purity synthetic mineral. After crushing and shaping, magnetic separation to remove iron, and sieving into various particle sizes. It has a dense texture, high hardness, sharp horn-shaped grains, high refractoriness, and is very hard and corrosion-resistant.

Feature of White Fused Alumina

The hardness of White Aluminium Oxide is slightly higher than that of brown aluminium oxide, the toughness is slightly lower, the purity is high, the self-sharpening is good, the grinding ability is strong, the calorific value is small, the efficiency is high, the acid and alkali corrosion resistance, and the high temperature thermal stability is good. Made of white aluminium oxide sand, it is suitable for grinding fine-grained abrasives such as high carbon steel, high speed steel and stainless steel. White aluminium oxide segment sand can also be used for precision casting and advanced refractories.

Physical and chemical indicators: Al2O3≥99% Na2O≤0.5% CaO ≤0.4% Magnetic substance ≤0.003%.

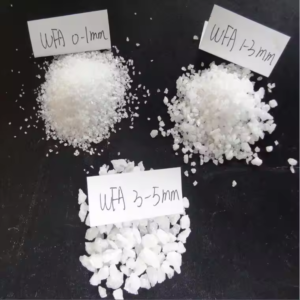

Sand Size: 8-5mm 5-3mm、3-1mm 1-0mm

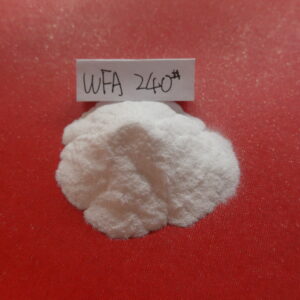

Powder: 320-0, 280-0, 240-0, 200-0, 180-0, 150-0, 120-0, 100-0

Sand Model: F8, F10、F12 F14, F16, F20, F22, F24, F30, F36, F40, F46, F54, F60, F70, F80, F90, F100, F120, F150, F180, F220.

Micro powder: W63, W50, W40, W28, W20, W14, W10, W7, W5, W3.5, W2.5, W1.5, W1, W0.5

Application Area of White Fused Alumina

- Shaped and unshaped refractories

- Abrasive products

- Welding fluxes

- Blasting media

- Brake and friction linings

- Laminating flooring

Advantages of White Fused Alumina

- depending on processing: the grain shape is round or splintered

- high hardness of 9 (Mohs)

- density of 3.95 g/cm³

- chemically inert

- high chemical resistance

- narrow grain size distribution

- transparent performance in many binding systems

| Index | Al2O3 | SiO2 | Fe2O3 | Na2O | TiO2 |

| Typical value | 99.18 | 0.047 | 0.05 | 0.31 | 0.01 |